CORPORATE PROFILE

History of Setia Precast Sdn Bhd

The history of S P Setia's involvement in prefabricated construction dates back since 1982 when it teamed up with Taisei Prefab and Marubeni of Japan to undertake mass construction of prefabricated houses for a PKNS development in Shah Alam. The turnkey project involved the design and construction of 4,580 units of 5-storey medium cost apartments.

A joint venture was formalized on 17 June 1995 with the establishment of Pakar Precast Components Sdn Bhd, between Taisei Prefab Construction Co. Ltd. (Japan) and S P Setia Bhd. On 25 June 1998, the joint venture company changed its name to Setia Precast Sdn Bhd. In September 2001, S P Setia bought over the shares held by Taisei Prefab, making Setia Precast its wholly-owned subsidiary. Setia Precast continues to maintain close relations with Taisei Prefab through technical cooperation and exchange.

Over the years, Setia Precast has built a recognizable presence as the leader in prefabricated construction with successful large-scale construction schemes in Petaling Jaya, Klang, Seri Kembangan and Ampang. To date, S P Setia has built more than 35,000 units of prefabricated residential units in the country including about 5000 units of government apartments in Putrajaya.

Principal Activity

The Company is a specialist contractor for the construction of buildings using precast technology and associated works.

Share Capital

The present Authorized and Issued and Fully Paid-Up Share Capital of Setia Precast comprises RM10,000,000.00 ordinary shares of RM1.00 each.

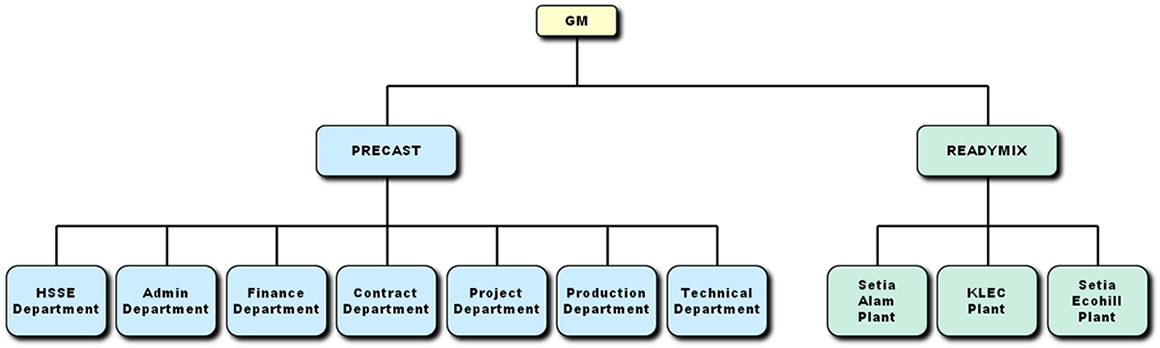

OUR ORGANIZATION

The Technical Team

The Technical Department will take lead in the full range of pre-planning works, from liaison with the consultants to finalization of all the dimensions, features and fitting as well as the designing of the precast components, the interface of in-situ and precast into detailed shopdrawings.

The Production Team

The Production Department is housed in two precast factories located at United Subang Jaya, Subang and Bandar Setia Alam, Shah Alam with an annual capacity to produce 2,000 and 2,500 units respectively. The strategic location of our plants with close proximity to major highways enables us to cater to the needs of a major portion of developments in the Klang Valley.

Our production activity in a factory-controlled environment allows us to ensure consistent quality and uniformity. The variables affecting the quality at site are nearly eliminated in such a controlled environment. In addition, the procurement of steel moulds to cast the variety of shapes and forms of precast panels has enable us to maintain consistency.

The Construction Team

Structural Features

The structural construction phase is divided into two concurrent processes, i.e production of precast structural components and the in-situ works at site. With the combination, we can guarantee timely management of the construction program with the existence of buffer stocks at the factory to cater to any delay due to material or weather problems.

CERTIFICATES & AWARDS

Certification and Authority Registration

SGS Yarsley United Kingdom has certified Setia Precast Sdn Bhd as meeting the ISO 9002 Standards for its Quality Management System in the construction of residential units using precast technology since August 1999. In 2002, Setia Precast's quality certification was upgraded to ISO 9001. Following this, the scope of the ISO 9001 certification was extended to cover the manufacturing of ready-mix concrete in 2004. On 20 September 2005, Setia Precast's quality certification was successfully upgraded to ISO 9001:2000. On 20 August 2011, the certification again was successfully upgraded to ISO 9001:2008 as a testament to its high quality standards.

Milestone:

1999 -- Achieved ISO 9002

2002 -- Upgraded to ISO 9001

2004 -- Extended Scope Construction of Residential Units Utilizing the Precast Technology and Manufacture of Ready-Mix Concrete.

2005 -- Awarded The Malaysian Construction Industry Excellence Awards 2005 under the Project Award for Major Scale Project (Building)

-- Upgraded to ISO 9001:2000

2006 -- Contributed IBS Component for ‘The Full Scale IBS Structure’ located at IBS Centre, CIDB

2011 -- Awarded The Malaysian Construction Industry Excellence Awards 2011 under IBS Award Category (Main Contractor & IBS Supplier for Setia Putrajaya Development Sdn Bhd)

-- Upgraded to ISO 9001:2008

2013 -- Awarded The Malaysian Construction Industry Excellence Awards 2013 under IBS Award Category

* Click the images to enlarge the Certificates & Awards.

ISO Certification

ISO 9001:2008 Certification

Authority Registration

Construction Industry Development Board Malaysia (CIDB) Registration

Contractor Registration Board (Government Project) PKK Registration

Our Quality Management

Our daily operations and workflow adheres to the policies and procedures documented in the ISO 9001:2008 standards to ensure top-notch efficiency and productivity.

S P Setia has also spearheaded a life-long learning and training program towards continued improvement in all aspects of Services, People and Product Quality through S P Setia Academy.

Guided by these two Quality Management Programs, Setia Precast will strive to live up to its reputation as an industry leader to continuously improve and innovate workflows and products to set new benchmarks in the IBS industry.

Malaysian Construction Industry Excellence Awards (MCIEA) 2005

OSH Excellence Award For Contractor 2005

Malaysian Construction Industry Excellence Awards (MCIEA) 2011

Malaysian Construction Industry Excellence Awards (MCIEA) 2013

Setia Precast was the winner of the Major Scale Project Category of the Malaysian Construction Industry Excellence Awards (MCIEA) 2005 organized by the Construction Industry Development Board (CIDB). Setia Precast won the award based on its success in employing the IBS in the construction of the Putrajaya Parcel 8 Project involving 2 blocks of 684 apartment units and a public amenity building in Precinct 9, Putrajaya.

Setia Precast was also the recipient of the OSH Excellence Award for Contractor 2005 given by Malaysian Occupational Safety and Health Professional's Association (MOSHPA) and Social Security Organization (SOCSO).

Setia Precast once again became the winner of CIDB's MCIEA 2011 but this time in IBS Award Category (participated with Setia Putrajaya Development Sdn Bhd). The award was based on the success in employing IBS in the construction of the Putrajaya Parcel 12B Project involving 8 blocks of 8 to 18-storey 810 apartment units and a public amenity building in Precinct 15, Putrajaya.

The recognition did not end there. With the completion of the Specialist Complex and Ambulatory Care Centre (SCACC), and Hospital Kuala Lumpur (HKL), Setia Precast was awarded the IBS Award, in the MCIEA 2013. The award was based on the success in adopting more than 70% of IBS component for construction of the said project involving 8-storey V-shaped block with 2½-storey car park within HKL along Jalan Pahang, Kuala Lumpur Federal Territory.

These awards underscore Setia Precast's commitment as the frontrunner for the construction industry especially in answering the government's call to actively adopt IBS technologies in line with efforts to modernise the sector.

For more information on our awards and achievements, please visit our corporate website.